STORE IT DON’T POUR IT

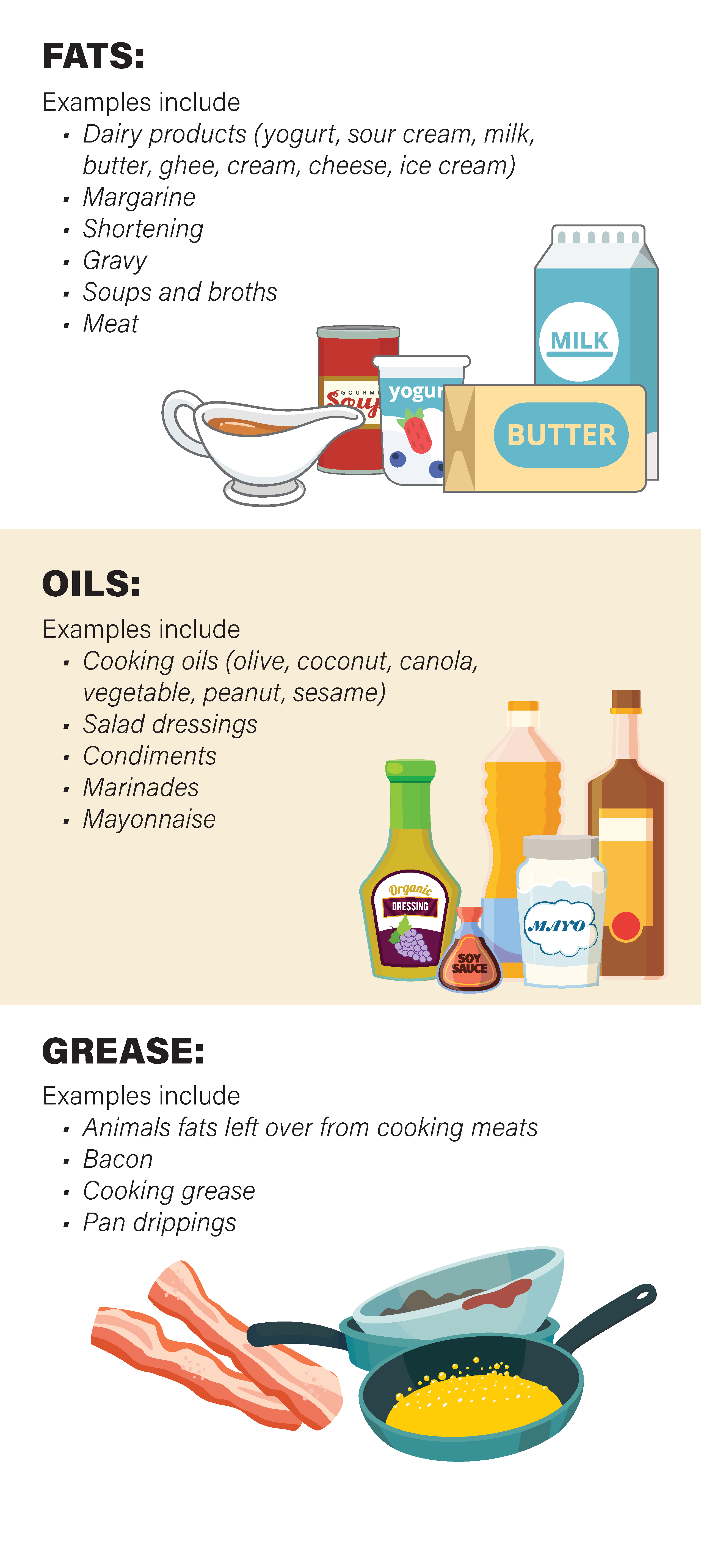

Fats, oils, and grease from food products and by products of cooking, such as butter, margarine, lard, shortening, cooking oils, soups, vegetable oils, salad dressings, meat fat, sauces and gravies, condiments, dairy products, nuts, and sandwich spreads, are hazardous to your pipes, sewer systems and the environment. When fats, oils and grease are poured down the drain and enter the sewer system, they will cool, harden and stick to the inner walls of the pipes. Even small amounts will add up over time, and eventually this material builds up, restricting wastewater flow, causing odors and even leading to messy and expensive clogged pipes, floodings and sewer back-ups. Repairing sewage infrastructure can lead to increased water rates.

What you CAN DO with your Fats, Oils, Grease

- Do Wipe grease from cooking equipment using paper towel or absorbents before washing and put it in the compost.

- Do Recycle oil

- Do Place grease from cooking into a container (can or jar) to cool and solidify before disposal.

- Do Scrape expired dairy into the compost bin.

- Do Scrape food scraps into the compost bin.

DON’T!

- Don’t pour or rinse fats, oils and grease down sinks, drains, or toilets (they all lead to the same place).

- Don’t use reuseable cloths or rags because when washed, it will still end up in your pipes.

- Don’t drain turkey drippings or gravy down the drain or toilet.

- Don’t use chemical drain cleaners, they can damage pipes and wastewater treatment systems, and they are ineffective at removing buildup.

- Don’t run hot water over dishes, pans, fryers or griddles to wash oil and grease down the drain.

Commerical Establishments

Protect your kitchen’s plumbing, the wastewater treatment plants and the environment. And save yourself $$s in repairs!

- Wipe fats, oils, and grease (FOG) and scrape food waste from all dishes into the waste bin before washing or soaking.

- Install, clean, inspect and regularly maintain a grease interceptor system.

- Properly dispose of FOG and food waste contents.

- ECODINE, Calgary

- Redux, Calgary

- All Bins Ltd., Calgary

- Cascades Recovery+, Calgary

- Shepard Landfill, Calgary

- Airdrie Recycle Depot, Airdire

- 310-Dump, Calgary

- Super Save Group, Calgary

- Collective Waste Solutions, Calgary

- Harvest Recycling, Calgary

- Grease interceptor service providers may take care of the disposal as well.

- Recycle used deep fryer oil using a service provider and keep bin areas clean from spills.

- ECODINE

- Redux

- Ensure FOG is not disposed of into the environment or stormwater system.

- Use a kitchen strainer to prevent food residue from going down the drain.

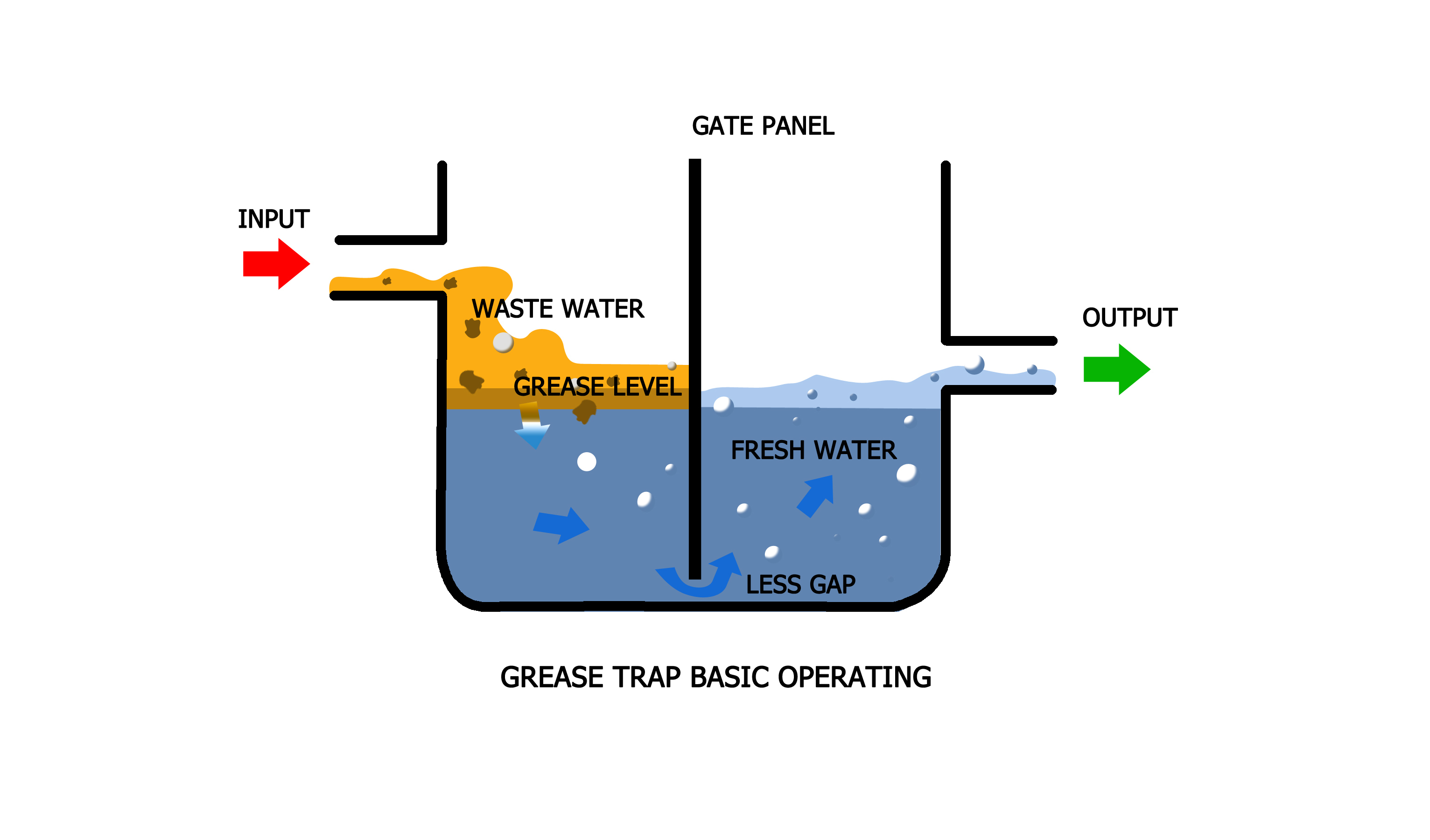

As wastewater enters the grease interceptor, it slows down the flow of water significantly. This allows the fats, oils and grease to float to the top, while the solids will sink to the bottom. This leaves only the wastewater to continue flowing out of the grease interceptor.

Contact a plumber to properly size a grease interceptor that will be in accordance with the national plumbing code of Canada.

If FOG is spilled outside, it should be cleaned up immediately.

If the spill is absorbed into the ground or enters the stormwater system it must be reported to Alberta Environment and Protected Areas (AEPA) and Rocky View County by calling 403-230-1401. This includes FOG spills around used oil containers.

Along with several federal and provincial regulations, there are some conditions under the Wastewater Bylaw

C-7662-2017 related to proper FOG management. Failure to follow these conditions can result in fines for your food service establishment.

Interceptors (Rocky View County BYLAW)

28.01 Interceptors shall be provided for all garages, restaurants, automotive service stations and vehicle and equipment washing establishments and for other types of business when required by the Regulations or, in the opinion of the Manager, such Interceptors are necessary for the proper handling of liquid wastes containing grease in excessive amounts, or any flammable wastes, sand, mud or other harmful ingredients.

28.02 All Interceptors shall be of a type and capacity which conform to the Regulations and shall be located so as to be readily and easily accessible for cleaning and inspection.

28.03 All Interceptors shall be maintained at all times in satisfactory and effective operation by the Owners of the properties on which they are installed at the Owner's expense.

28.04 All Interceptors shall be connected to the Sewer unless the Manager shall otherwise stipulate.

28.05 If the drainage system in any new commercial or industrial building includes an Interceptor, then a Control Manhole is required.

28.06 Garage Drains connected to a Sanitary Sewer, or a Service Connection which is in turn connected to a Sanitary Sewer, must have a mud Interceptor of sufficient size and design to effectively trap solids.

SCHEDULE “D”

3 (g) Surcharge – respecting discharge of Wastewater in excess of bylaw parameters including, without restriction, a Rate for: i. volume Wastewater discharged in excess of standard rate limits; ii. Overstrength Wastewater; and iii. prohibited/restricted discharge of uncontaminated water;

4. Charges Where specific Rates have not been established by Council for a particular service, the County shall charge for services provided based upon an actual cost recovery basis including but not limited to charges of $50.00 per hour where County employees perform the service. All hourly rates shall be based upon a minimum two (2) hour basis. Without limiting the generality of the foregoing, the County may establish Charges for the following:

h. clearing of blocked Sewer, including labour, vehicles and equipment.

Improper disposal of select materials may result in overstrength surcharges. Below are the overstrength rates as per Rocky View County Master Rates Bylaw:

| Per mg/L over 300 mg/L biological oxygen demand (BOD) |

$0.1460 |

| Per mg/L over 300 mg/L total suspended solids (TSS) |

$0.1161 |

| Per mg/L over 100 mg/L fats, oil and grease (FOG) |

$0.1971 |

- Remove the lid from the grease interceptor.

- Break through the FOG layer on the top and determine the depth of water layer.

- If the FOG layer is two inches thick or more, or if the combined total of FOG and solids reaches 25% of the wet space in the interceptor, it is time to clean your grease interceptor.

- If the FOG layer is solidified or hard to break through, the grease interceptor needs to be cleaned more often to prevent potential sewer back-ups.

- Open the grease interceptor and scoop out the layer of FOG on the top for disposal (see below for disposal instructions).

- Use a wet-dry vacuum to suction out the liquid layer, leaving solids at the bottom of the interceptor

- Scrape the sides of the interceptor and the baffles (if detachable, remove the baffles for cleaning).

- Scoop out the solids and scraped material from the bottom of the interceptor for disposal.

- Using fresh water and a scraping tool or brush, thoroughly clean the entire inside of the interceptor and suction out the remaining waste material.

- Rinse the grease interceptor with clean water and suction out one last time.

- Ensure that the inlet, outlet and air relief ports are clean and clear of obstructions.

- Inspect all components for any corrosion or damage and ensure that all components are working properly.

- If required, contact a grease interceptor cleaning company or plumber for repairs.

- Properly reinstall any removed seals or baffles.

- Securely fasten the cover and fill the grease interceptor with clean water to ensure maximum efficiency and to reduce odors.

- Open the wet-dry vacuum and scoop out any additional material that has separated for disposal. Remove any solids for disposal and pour the remaining water back into the sink.

- Completely disinfect the sink, as per Alberta Health Services requirements.

- Document the cleaning for your records, which must be kept for a minimum of two years. Download a maintenance record form.

The fats, oils and grease (top layer), and solids (bottom layer) should be removed from the grease interceptor and placed into your waste bin. It should be placed in the waste bin in a way that it will not spill (E.g. double bagged)

- Grease interceptor contents are not to be disposed of into the environment, wastewater sewer system or stormwater system.

- There are service providers who can handle the cleaning and disposal of grease interceptor contents.

You are required to properly document and report all grease interceptor inspections/cleanings. This involves documenting inspections on a maintenance record form, such as the one provided on the page below. You are also required to take dated photographs (use a dated newspaper or the date on a phone) of the grease interceptor before and after the cleaning/inspection. You will be required to maintain 2 years of documentation on file.

A written record of all maintenance, cleaning and inspections of your fats, oils and grease (FOG) must be kept on file for two years. The form is available here.

Problematic substances

Automotive service stations and vehicle/equipment washing stations use many substances that can be harmful to the wastewater and stormwater systems. These substances can cause costly wastewater damages, fines and could damage the environment.

|

Problematic substances

|

Sources

|

|

Glycol

|

Anti-freeze

|

|

Phosphorus

|

Detergents, leaners and exterior finishes

|

|

Hydrocarbons

|

FOG, solvents, flammable liquids and automotive fluids

|

|

Metals and solids

|

Rust, sand, sediment and paint chips

|

Pre-treatment systems

Pre-treatment systems such as sump pumps, interceptors and oil-water separators are a cost-effective way of preventing unwanted waste from entering the wastewater system. As mentioned in bylaw 28.01, interceptors are required for automotive service stations and vehicle/equipment washing stations. The maintenance and cleaning guide will be the exact same as the one mentioned for food service establishments. A written record of all maintenance, cleaning and inspection of the interceptor must be kept on file for two years. Similarly to food service establishments, dated photographs (use a dated newspaper or the date on a phone) from before and after are required. You can use the maintenance record form provided on the page above.